Polovna kompletna linija za flaširanje mirnog vina – 8000 boca na satAPE Impianti

Polovna kompletna linija za flaširanje mirnog vina – 8000 boca na sat

APE Impianti

Stanje

Polovno

Lokacija

Italija

Slike prikazuju

Prikaži kartu

Podaci o mašini

Cijena i lokacija

- Lokacija:

- , Italija

Pozovite

Detalji ponude

- ID oglasa:

- A21193520

- Referentni broj:

- LC597

- Ažuriranje:

- posljednji put 09.02.2026

Opis

Technical Specifications & Performance Data

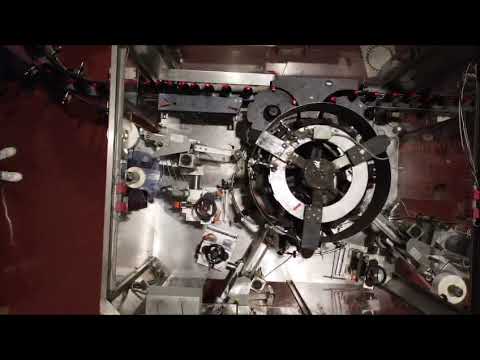

This used bottling line is engineered for reliable beverage production and downstream industrial packaging at up to 8,000 bph. The configuration integrates APE Impianti case handling with KOSME labeling technology, offering robust performance for second hand applications and flexible format management typical of glass and PET bottle operations.

Production speed: 8,000 bottles per hour

Compatible formats: Typical case pack pattern includes 12 x 0.75L; additional formats manageable with change parts

Containers: Designed for bottle handling; configuration suitable for PET and Glass (cylindrical containers)

Labeling modules: KOSME STAR 720 12T (cold glue), KOSME EXTRA ADHESIVE 12T S3 E3 (self-adhesive)

Packaging modules: APE FORMA 2000 (case erector), APE INCA 2010 (case packer), APE INSER 2001 (divider inserter)

Electrical (labelers): 400 V, 50 Hz; installed power 4 kW (STAR 720 12T) and 8 kW (EXTRA ADHESIVE 12T S3 E3)

Weights (labelers): 2650 kg (STAR 720 12T), 2000 kg (EXTRA ADHESIVE 12T S3 E3)

Compliance: CE-marked components

Advanced Automation & Control Systems

The line leverages modular automation across labeling and case-handling stations for stable throughput. Operator-friendly controls on each module support quick setup and changeover. The KOSME labeling machines feature standardized European electrical specifications (400 V, 50 Hz) and balanced installed power to ensure precise label application at line speed. APE Impianti packaging modules provide synchronized motion and interlocked safety protections for downstream operations.

Integrated start/stop logic and line accumulation to stabilize flow

Fast mechanical adjustments for changeovers with guided setup steps

Interlocked guards and emergency stops on major equipment

Clear HMI/controls per machine for format selection and diagnostics

Production Line Integration Capabilities

This production line is designed to operate inline with conveyors and accumulation to match the 8,000 bph target. The dual-labeling architecture—cold glue and self-adhesive—supports a wide range of label materials and presentation standards. Case forming, partition insertion, and packing are fully integrated for efficient end-of-line handling, enabling consistent case quality for logistics and storage.

Inline configuration with upstream/downstream equipment compatibility

Cold glue and self-adhesive labeling flexibility for front/back and wrap-around applications

Case erecting, divider inserting, and packing for 12 x 0.75L patterns

Suitable for multiple bottle sizes with appropriate change parts

Machine Condition & Maintenance History

Dedpeyh E Husfx Ab Isun

This is a second hand, pre-owned bottling and packaging solution with component build years ranging from 1998 to 2016. The equipment is CE-compliant and represents proven European engineering for beverage production. Standard preventive maintenance routines, lubrication points, and wear-part kits are typical for these models, supporting reliable recommissioning.

Operational Performance & Versatilit...

This used bottling line is engineered for reliable beverage production and downstream industrial packaging at up to 8,000 bph. The configuration integrates APE Impianti case handling with KOSME labeling technology, offering robust performance for second hand applications and flexible format management typical of glass and PET bottle operations.

Production speed: 8,000 bottles per hour

Compatible formats: Typical case pack pattern includes 12 x 0.75L; additional formats manageable with change parts

Containers: Designed for bottle handling; configuration suitable for PET and Glass (cylindrical containers)

Labeling modules: KOSME STAR 720 12T (cold glue), KOSME EXTRA ADHESIVE 12T S3 E3 (self-adhesive)

Packaging modules: APE FORMA 2000 (case erector), APE INCA 2010 (case packer), APE INSER 2001 (divider inserter)

Electrical (labelers): 400 V, 50 Hz; installed power 4 kW (STAR 720 12T) and 8 kW (EXTRA ADHESIVE 12T S3 E3)

Weights (labelers): 2650 kg (STAR 720 12T), 2000 kg (EXTRA ADHESIVE 12T S3 E3)

Compliance: CE-marked components

Advanced Automation & Control Systems

The line leverages modular automation across labeling and case-handling stations for stable throughput. Operator-friendly controls on each module support quick setup and changeover. The KOSME labeling machines feature standardized European electrical specifications (400 V, 50 Hz) and balanced installed power to ensure precise label application at line speed. APE Impianti packaging modules provide synchronized motion and interlocked safety protections for downstream operations.

Integrated start/stop logic and line accumulation to stabilize flow

Fast mechanical adjustments for changeovers with guided setup steps

Interlocked guards and emergency stops on major equipment

Clear HMI/controls per machine for format selection and diagnostics

Production Line Integration Capabilities

This production line is designed to operate inline with conveyors and accumulation to match the 8,000 bph target. The dual-labeling architecture—cold glue and self-adhesive—supports a wide range of label materials and presentation standards. Case forming, partition insertion, and packing are fully integrated for efficient end-of-line handling, enabling consistent case quality for logistics and storage.

Inline configuration with upstream/downstream equipment compatibility

Cold glue and self-adhesive labeling flexibility for front/back and wrap-around applications

Case erecting, divider inserting, and packing for 12 x 0.75L patterns

Suitable for multiple bottle sizes with appropriate change parts

Machine Condition & Maintenance History

Dedpeyh E Husfx Ab Isun

This is a second hand, pre-owned bottling and packaging solution with component build years ranging from 1998 to 2016. The equipment is CE-compliant and represents proven European engineering for beverage production. Standard preventive maintenance routines, lubrication points, and wear-part kits are typical for these models, supporting reliable recommissioning.

Operational Performance & Versatilit...

Dokumenti

Dobavljač

Napomena: Registrujte se besplatno ili prijavite, za pristup svim informacijama.

Registriran od: 2021

Pošaljite upit

Telefon & Faks

+39 344 0... oglasi

Ovi oglasi bi vas također mogli zanimati.

Mali oglas

Fumane (Verona)

Fumane (Verona)

567 km

Case Packer

APE ImpiantiInca 2001

APE ImpiantiInca 2001

Mali oglas

Fumane (Verona)

Fumane (Verona)

567 km

Case Erector

APE ImpiantiForm 1200 HM

APE ImpiantiForm 1200 HM

Mali oglas

Fumane (Verona)

Fumane (Verona)

567 km

Case Packer

APE ImpiantiINCA 2000

APE ImpiantiINCA 2000

Mali oglas

Fumane (Verona)

Fumane (Verona)

567 km

Case Erector

APE ImpiantiForm 2000 HM SX

APE ImpiantiForm 2000 HM SX

Mali oglas

Fumane (Verona)

Fumane (Verona)

567 km

Case Erector

APE ImpiantiFORM1500 HMB

APE ImpiantiFORM1500 HMB

Vaš oglas je uspješno izbrisan

Došlo je do greške