Stol za rezanje staklaBottero

301C

Stol za rezanje stakla

Bottero

301C

Godina proizvodnje

1994

Stanje

Polovno

Lokacija

Minnertsga

Slike prikazuju

Prikaži kartu

Podaci o mašini

- Naziv mašine:

- Stol za rezanje stakla

- Proizvođač:

- Bottero

- Model:

- 301C

- Godina proizvodnje:

- 1994

- Stanje:

- polovno

Cijena i lokacija

- Lokacija:

- De Opfeart 26, 9047 KW Minnertsga, Niederlande

Pozovite

Detalji ponude

- ID oglasa:

- A20846677

- Ažuriranje:

- posljednji put 31.12.2025

Opis

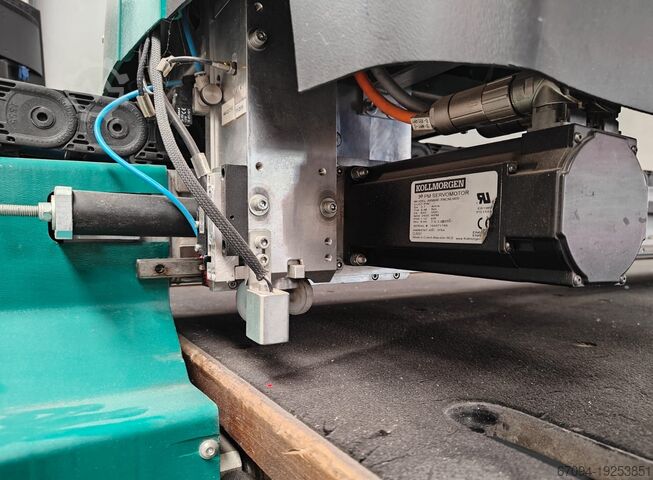

The Bottero 301C is a laminated glass cutting machine specifically designed for cutting and separating laminated glass. Key specifications include: weight approx. 2.8 tons, power rating 10–11 kVA, maximum cutting length 3400 mm, glass thickness 3–10 mm (monolithic up to 19 mm), 380 V/50 Hz connection.

Technical Data Bottero 301C

Make/Model: Bottero 301C

Chassis number: GG301C-164

Year of manufacture: 1994

Fedpsx Rhczefx Adbspb

Machine type: Laminated glass cutting table (semi-automatic)

Weight: approx. 2,800 kg

Power consumption: 10.9 kVA – 50 Hz

Electrical connection: 380 V

Machine dimensions: Length 4,900 mm, width 3,350 mm, working height 930 mm

Transport dimensions: approx. 4.2 × 2.4 m + 4.8 × 1.0 × 1.6 m

Glass thickness: 3 – 10 mm laminated, 33.1 – 66.2 mm PVB; monolithic up to 19 mm possible

Maximum cutting length: 3,400 mm

Functions: Cutting, breaking, and separation of laminated glass

with patented PVB system

Worktable with pneumatic air cushion

Covered with wool felt for optimal flatness

Lifting arms: Pneumatic, max. load 280 kg

Control: Electromechanical, manual pressure adjustment, and photocell for glass dimension detection

Practical Features

- Air cushion system: A high-performance fan generates an air cushion, facilitating the movement of glass sheets.

- Cutting module: Patented Bottero system with integrated heater for PVB separation, automatic lubrication, and adjustable cutting pressure.

- Flexibility: Capable of cutting both laminated glass (with PVB interlayer) and monolithic glass.

- Lifting arms: Pneumatically operated, suitable for sheets up to 280 kg.

- Worktable: Covered with wool felt for minimal friction and precise flatness.

Application

The Bottero 301C is ideal for companies processing large quantities of laminated glass (e.g., safety glass or insulating glass). Thanks to its semi-automatic cutting and separation system, glass can be handled efficiently and free of splinters, increasing both productivity and quality.

Oglas je automatski preveden. Moguće su greške u prijevodu.

Technical Data Bottero 301C

Make/Model: Bottero 301C

Chassis number: GG301C-164

Year of manufacture: 1994

Fedpsx Rhczefx Adbspb

Machine type: Laminated glass cutting table (semi-automatic)

Weight: approx. 2,800 kg

Power consumption: 10.9 kVA – 50 Hz

Electrical connection: 380 V

Machine dimensions: Length 4,900 mm, width 3,350 mm, working height 930 mm

Transport dimensions: approx. 4.2 × 2.4 m + 4.8 × 1.0 × 1.6 m

Glass thickness: 3 – 10 mm laminated, 33.1 – 66.2 mm PVB; monolithic up to 19 mm possible

Maximum cutting length: 3,400 mm

Functions: Cutting, breaking, and separation of laminated glass

with patented PVB system

Worktable with pneumatic air cushion

Covered with wool felt for optimal flatness

Lifting arms: Pneumatic, max. load 280 kg

Control: Electromechanical, manual pressure adjustment, and photocell for glass dimension detection

Practical Features

- Air cushion system: A high-performance fan generates an air cushion, facilitating the movement of glass sheets.

- Cutting module: Patented Bottero system with integrated heater for PVB separation, automatic lubrication, and adjustable cutting pressure.

- Flexibility: Capable of cutting both laminated glass (with PVB interlayer) and monolithic glass.

- Lifting arms: Pneumatically operated, suitable for sheets up to 280 kg.

- Worktable: Covered with wool felt for minimal friction and precise flatness.

Application

The Bottero 301C is ideal for companies processing large quantities of laminated glass (e.g., safety glass or insulating glass). Thanks to its semi-automatic cutting and separation system, glass can be handled efficiently and free of splinters, increasing both productivity and quality.

Oglas je automatski preveden. Moguće su greške u prijevodu.

Dobavljač

Napomena: Registrujte se besplatno ili prijavite, za pristup svim informacijama.

Registriran od: 2019

Pošaljite upit

Telefon & Faks

+31 518 4... oglasi

Ovi oglasi bi vas također mogli zanimati.

Mali oglas

Maitratten

Maitratten

434 km

Mašina za pranje stakla

BAVELLONILV 1604-20 Glaswaschmaschine

BAVELLONILV 1604-20 Glaswaschmaschine

Mali oglas

Njemačka

Njemačka

972 km

Pogon za proizvodnju izolacionog stakla

Forel2000

Forel2000

Mali oglas

Pleystein

Pleystein

752 km

Mašina za brušenje stakla

Glasschleifmaschine ZXMmit 9 Spindel

Glasschleifmaschine ZXMmit 9 Spindel

Mali oglas

Njemačka

Njemačka

972 km

Industrijski roboti

Kuka KUKAKR30L16-2 (SafeRobot)

Kuka KUKAKR30L16-2 (SafeRobot)

Mali oglas

Diest

Diest

1.235 km

Sto za rezanje stakla

BAVELLONILAMY 370 S

BAVELLONILAMY 370 S

Mali oglas

Maasmechelen

Maasmechelen

1.195 km

Sto za rezanje stakla

Bottero353BKM-J

Bottero353BKM-J

Mali oglas

Bad Waltersdorf

Bad Waltersdorf

387 km

Stol za podizanje i rezanje stakla

Hegla

Hegla

Mali oglas

Pleystein

Pleystein

752 km

Sto za rezanje stakla

Pannkoke Floatschneidetischfür Geteilte Bandmaße

Pannkoke Floatschneidetischfür Geteilte Bandmaße

Mali oglas

Dobrzykowice

Dobrzykowice

801 km

Mlin za staklo

Zafferani Glas

Zafferani Glas

Mali oglas

Berlin

Berlin

1.005 km

Modul za bušenje

FischerVB 240nc

FischerVB 240nc

Vaš oglas je uspješno izbrisan

Došlo je do greške