Ravna štanca, hot stamping, multiGRAFOTRONIC

350 200254G

Ravna štanca, hot stamping, multi

GRAFOTRONIC

350 200254G

VB plus PDV

67.500 €

Stanje

Polovno

Lokacija

Kruszyn Krajeński

Slike prikazuju

Prikaži kartu

Podaci o mašini

- Naziv mašine:

- Ravna štanca, hot stamping, multi

- Proizvođač:

- GRAFOTRONIC

- Model:

- 350 200254G

- Stanje:

- vrlo dobro (rabljeno)

- Funkcionalnost:

- potpuno funkcionalan

Cijena i lokacija

VB plus PDV

67.500 €

- Lokacija:

- Ceramiczna 15, 86-005 Białe Błota, PL

Pozovite

Detalji ponude

- ID oglasa:

- A18949116

- Ažuriranje:

- posljednji put 29.12.2025

Opis

Segment I – Unwinder with stabilizing table

The first segment is responsible for stable guidance of the material web. It is equipped with pins enabling both lamination and delamination of the face with liner or other raw material. It has a laminator with the possibility of precise pressure adjustment.

In addition:

• The hanging mechanism in each segment allows for continuous operation, eliminating the need to stop the machine while the flat die is working.

• Leading (pulling) servomotors ensure precise control of the material, also located in the station.

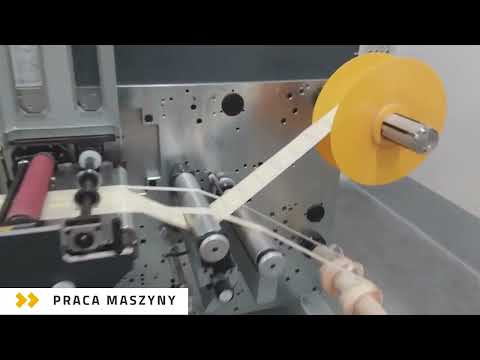

Segment II – Central (Die)

The heart of the machine is the flat die, allowing for cutting and embossing.

It has been equipped with:

• Hot stamping system – thanks to the heated plate with a mounted matrix, it allows for the application of effective decorations.

• Upper foil unwinders enabling additional material processing.

• Manual pressure adjustment – four independent clocks provide full control over the process, which is particularly important for irregular matrices and unconventional work.

• Lower trolley as an alternative to the hanging system – used depending on the specifics of the work.

Segment III – Puncher

The third segment is responsible for separating cut labels and transporting them to the receiving tray.

• Puncher – precise separation of single labels.

• Two laminators – one on each side of the puncher, with adjustable pressure.

• Unwinders and winders ensuring smooth guidance of additional raw material.

Segment IV – Rewinder

The last segment is responsible for the final winding of the finished material.

Equipped with:

• Two mandrels – enabling simultaneous or alternate winding of the finished product.

• Web tensioning system (nip holding and web tensioning) – ensuring stable guidance of the material.

• Slitting disc knife station.

• Whisk (waste) extraction system.

• Web sensors placed under each overhang, ensuring optimal process control.

Additional functionalities

Hfsdpowck U Refx Ab Ijc

• Remote control – the machine can be operated via the tablet included in the set.

• Mark sensor system (register) – precisely matches previously printed raw material, ensuring high accuracy and repeatability of production.

Oglas je automatski preveden. Moguće su greške u prijevodu.

The first segment is responsible for stable guidance of the material web. It is equipped with pins enabling both lamination and delamination of the face with liner or other raw material. It has a laminator with the possibility of precise pressure adjustment.

In addition:

• The hanging mechanism in each segment allows for continuous operation, eliminating the need to stop the machine while the flat die is working.

• Leading (pulling) servomotors ensure precise control of the material, also located in the station.

Segment II – Central (Die)

The heart of the machine is the flat die, allowing for cutting and embossing.

It has been equipped with:

• Hot stamping system – thanks to the heated plate with a mounted matrix, it allows for the application of effective decorations.

• Upper foil unwinders enabling additional material processing.

• Manual pressure adjustment – four independent clocks provide full control over the process, which is particularly important for irregular matrices and unconventional work.

• Lower trolley as an alternative to the hanging system – used depending on the specifics of the work.

Segment III – Puncher

The third segment is responsible for separating cut labels and transporting them to the receiving tray.

• Puncher – precise separation of single labels.

• Two laminators – one on each side of the puncher, with adjustable pressure.

• Unwinders and winders ensuring smooth guidance of additional raw material.

Segment IV – Rewinder

The last segment is responsible for the final winding of the finished material.

Equipped with:

• Two mandrels – enabling simultaneous or alternate winding of the finished product.

• Web tensioning system (nip holding and web tensioning) – ensuring stable guidance of the material.

• Slitting disc knife station.

• Whisk (waste) extraction system.

• Web sensors placed under each overhang, ensuring optimal process control.

Additional functionalities

Hfsdpowck U Refx Ab Ijc

• Remote control – the machine can be operated via the tablet included in the set.

• Mark sensor system (register) – precisely matches previously printed raw material, ensuring high accuracy and repeatability of production.

Oglas je automatski preveden. Moguće su greške u prijevodu.

Dobavljač

Napomena: Registrujte se besplatno ili prijavite, za pristup svim informacijama.

Registriran od: 2020

Pošaljite upit

Telefon & Faks

+48 52 37... oglasi

Ovi oglasi bi vas također mogli zanimati.

Mali oglas

Kaunas

Kaunas

1.305 km

Fleksografska štamparska mašina

MPSEF 330/ 7 color

MPSEF 330/ 7 color

Mali oglas

Leinfelden-Echterdingen

Leinfelden-Echterdingen

843 km

FGT grafički strojevi - pretvaranje

GMFB 3300 - Hotfoil/Screen etc.

GMFB 3300 - Hotfoil/Screen etc.

Mali oglas

Langenfeld (Rheinland)

Langenfeld (Rheinland)

1.134 km

Mašina za digitalnu štampu

XeroxiGen 5 Press incl. 5th colour

XeroxiGen 5 Press incl. 5th colour

Mali oglas

München

München

665 km

PITNEY BOWES DI425

Pitney BowesDI425

Pitney BowesDI425

Mali oglas

Bad Kreuznach

Bad Kreuznach

994 km

Fleksografska štamparska mašina

SMO Sondermaschinenbau OscherslebenEDM 200

SMO Sondermaschinenbau OscherslebenEDM 200

Mali oglas

Leinfelden-Echterdingen

Leinfelden-Echterdingen

843 km

FGT grafički strojevi - pretvaranje

GMDC 330 - Age: 2016!

GMDC 330 - Age: 2016!

Mali oglas

Kaunas

Kaunas

1.305 km

Rewer

Jurmet

Jurmet

Mali oglas

Helmstedt

Helmstedt

1.051 km

Automatska šivaća mašina

Müller Martini3210

Müller Martini3210

Mali oglas

Leinfelden-Echterdingen

Leinfelden-Echterdingen

843 km

FGT Graphic Machinery - Label Finisher

ROTOFLEXR 1300

ROTOFLEXR 1300

Mali oglas

Dettelbach

Dettelbach

872 km

Shrink uređaj (mašina za ugaono zavarivanje + tunel)

SmipackWS 560 A + T 450

SmipackWS 560 A + T 450

Vaš oglas je uspješno izbrisan

Došlo je do greške