Mašina za punjenje vode, ulja, sapuna, AdBlueaPROTON EE-ELEKTRONIKA d.o.o

XFR1000

Mašina za punjenje vode, ulja, sapuna, AdBluea

PROTON EE-ELEKTRONIKA d.o.o

XFR1000

Godina proizvodnje

2025

Stanje

Novi

Lokacija

Šašinovec

Slike prikazuju

Prikaži kartu

Podaci o mašini

- Naziv mašine:

- Mašina za punjenje vode, ulja, sapuna, AdBluea

- Proizvođač:

- PROTON EE-ELEKTRONIKA d.o.o

- Model:

- XFR1000

- Godina proizvodnje:

- 2025

- Stanje:

- novo

- Funkcionalnost:

- potpuno funkcionalan

Cijena i lokacija

- Lokacija:

- Krcevina 4, 10360 Soblinec, Hrvatska

Pozovite

Tehnički detalji

- Ukupna širina:

- 2.400 mm

- Ukupna dužina:

- 15.000 mm

- Ukupna visina:

- 2.800 mm

- Pritisak:

- 8 šipka

- Snaga:

- 10,9 kW (14,82 KS)

- Prazna masa:

- 6.400 kg

- Ulazni napon:

- 400 V

- Minimalna masa punjenja (min.):

- 200 g

- Masa punjenja (maks.):

- 5.000 g

Detalji ponude

- ID oglasa:

- A17231422

- Ažuriranje:

- posljednji put 25.09.2025

Opis

XFR 1000

Liquid Media Filling Line

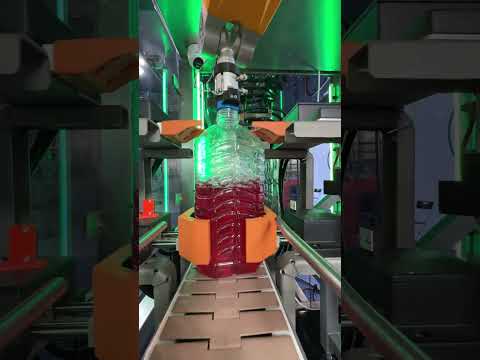

A fully automated liquid media filling line featuring robotic capping, automated handle placement, dual-sided labelling, optical quality control, and pallet wrapping.

An end-to-end solution covering the entire process, from bottle blowing to the palletizing and wrapping of filled bottles.

XFR LIQUILOAD

It enables optimal filling speeds for bottles of varying characteristics and liquids of different viscosities.

The machine’s easy configuration for different bottle types and corresponding liquids ensures quick adaptation to market demands.

• Capability to increase the number of nozzles

• Nozzles designed to prevent foaming of the liquid

• 800 to 4,000 filled bottles per hour

• Servo-driven nozzle positioning

• Easy configuration of new programs

XFR BOTTLELOCK

The machine segment performs fully automated capping of filled bottles.

Designed to accommodate various cap types, simplifying machine adjustments for seamless operation.

• Cap type adaptability

• Robotic bottle capping

• Optical inspection

• 800 to 2,000 capped bottles per hour

Hfsdpsuq Nv Tjfx Ab Ioc

XFR HANDLEGRIP

The automatic robotic placement of handles on bottles, while they move continuously towards the labeling machine, ensures seamless and uninterrupted operation.

• Adaptability to different handle types

• Robotic handle application on bottles

• Optical inspection for handle orientation verification

• Capability to attach handles with a funnel

XFR LABELFLOW

The machine applies the appropriate labels to both sides of the bottle, creating a finished appearance.

In the next phase, the labelled bottles undergo optical inspection.

• HERMA labelling system

• Simplified label type changeover

• Servo-driven for enhanced labeling precision

• Monitoring of remaining labels with operator alerts

OPTIONAL PARTS:

1. OPTICAL INSPECTION

Industrial cameras with integrated lighting and pneumatic ejection system.

2. PICK AND PLACE ROBOT

6-axis robot equipped with a 160 kg gripper for the current handling of 8 bottles onto a Euro pallet.

3. PALLETIZING

Palletizer with automatic pallet feeding via a roller conveyor to the bottle stacking area.

4. PALLET WRAPPING

The automatic pallet wrapper applies stretch film to palletized products, securing them for easier and safer transport.

5. FINISHED GOODS STORAGE

Finished pallets are transported to the warehouse via a metal roller conveyor.

6. REMOTE CUSTOMER SUPPORT

We provide remote support to ensure optimal machine performance.

7. ADDITIONAL OPTIONS

Automated data integration with ERP systems; RFID login; NFC detection of parts and tools; magnetically mounted tools.

8. MACHINE CONFIGURATION

Segments can operate independently or as an integrated solution, depending on the client's specific needs.

Proton EE-Elektronika d.o.o.

MachinFlex d.o.o.

Liquid Media Filling Line

A fully automated liquid media filling line featuring robotic capping, automated handle placement, dual-sided labelling, optical quality control, and pallet wrapping.

An end-to-end solution covering the entire process, from bottle blowing to the palletizing and wrapping of filled bottles.

XFR LIQUILOAD

It enables optimal filling speeds for bottles of varying characteristics and liquids of different viscosities.

The machine’s easy configuration for different bottle types and corresponding liquids ensures quick adaptation to market demands.

• Capability to increase the number of nozzles

• Nozzles designed to prevent foaming of the liquid

• 800 to 4,000 filled bottles per hour

• Servo-driven nozzle positioning

• Easy configuration of new programs

XFR BOTTLELOCK

The machine segment performs fully automated capping of filled bottles.

Designed to accommodate various cap types, simplifying machine adjustments for seamless operation.

• Cap type adaptability

• Robotic bottle capping

• Optical inspection

• 800 to 2,000 capped bottles per hour

Hfsdpsuq Nv Tjfx Ab Ioc

XFR HANDLEGRIP

The automatic robotic placement of handles on bottles, while they move continuously towards the labeling machine, ensures seamless and uninterrupted operation.

• Adaptability to different handle types

• Robotic handle application on bottles

• Optical inspection for handle orientation verification

• Capability to attach handles with a funnel

XFR LABELFLOW

The machine applies the appropriate labels to both sides of the bottle, creating a finished appearance.

In the next phase, the labelled bottles undergo optical inspection.

• HERMA labelling system

• Simplified label type changeover

• Servo-driven for enhanced labeling precision

• Monitoring of remaining labels with operator alerts

OPTIONAL PARTS:

1. OPTICAL INSPECTION

Industrial cameras with integrated lighting and pneumatic ejection system.

2. PICK AND PLACE ROBOT

6-axis robot equipped with a 160 kg gripper for the current handling of 8 bottles onto a Euro pallet.

3. PALLETIZING

Palletizer with automatic pallet feeding via a roller conveyor to the bottle stacking area.

4. PALLET WRAPPING

The automatic pallet wrapper applies stretch film to palletized products, securing them for easier and safer transport.

5. FINISHED GOODS STORAGE

Finished pallets are transported to the warehouse via a metal roller conveyor.

6. REMOTE CUSTOMER SUPPORT

We provide remote support to ensure optimal machine performance.

7. ADDITIONAL OPTIONS

Automated data integration with ERP systems; RFID login; NFC detection of parts and tools; magnetically mounted tools.

8. MACHINE CONFIGURATION

Segments can operate independently or as an integrated solution, depending on the client's specific needs.

Proton EE-Elektronika d.o.o.

MachinFlex d.o.o.

Dokumenti

Dobavljač

Napomena: Registrujte se besplatno ili prijavite, za pristup svim informacijama.

Registriran od: 2020

Pošaljite upit

Telefon & Faks

+385 43 3... oglasi

Ovi oglasi bi vas također mogli zanimati.

Mali oglas

Kirchheimbolanden

Kirchheimbolanden

975 km

Sistem označavanja za okrugle i četvrtaste kanistere

Weidmann Maschinen EtikettiermaschineFL-800

Weidmann Maschinen EtikettiermaschineFL-800

Mali oglas

Tata

Tata

417 km

Ekscentar presa AIDA NC2-250, 250 tona

AIDA NC2-2502-POINT ECCENTRIC GAP PRESS 250ton

AIDA NC2-2502-POINT ECCENTRIC GAP PRESS 250ton

Mali oglas

Niedźwiedź

Niedźwiedź

659 km

Kompresorska jedinica kondenzatorska jedinica

BITZERHSK7461-80-40P

BITZERHSK7461-80-40P

Mali oglas

Sonsbeck

Sonsbeck

1.200 km

Mašina za ispitivanje zatezanja univerzalna mašina za ispitivanje

Hegewald & PeschkeH5TMCI

Hegewald & PeschkeH5TMCI

Mali oglas

Njemačka

Njemačka

922 km

Parna turbina

Nadrowski BielefeldC4DS-GVI

Nadrowski BielefeldC4DS-GVI

Mali oglas

Nether Heage

Nether Heage

1.732 km

Rezervoar za skladištenje

Aluminium Bulk Silo21 individual silos

Aluminium Bulk Silo21 individual silos

Mali oglas

Hoofddorp

Hoofddorp

1.337 km

Visokobrzinska mašina za izradu papirnih

MASTER BAGMB300X

MASTER BAGMB300X

Mali oglas

Jüri

Jüri

1.786 km

Debarker

Valon Kone OYVK-550-Combi 2R/480(620)

Valon Kone OYVK-550-Combi 2R/480(620)

Mali oglas

Ostrołęka

Ostrołęka

1.059 km

Proizvodnja mlijeka i mliječnih proizvoda

MargoPasteryzator

MargoPasteryzator

Mali oglas

Helmstedt

Helmstedt

1.051 km

Vijčani kompresor 4 bara

KaeserCS 91

KaeserCS 91

Vaš oglas je uspješno izbrisan

Došlo je do greške