Depaneliranje / Obrada PCB-aSystemtechnik Hölzer GmbH

Nutzentrenner LOW 4233 XL RD

Depaneliranje / Obrada PCB-a

Systemtechnik Hölzer GmbH

Nutzentrenner LOW 4233 XL RD

Godina proizvodnje

2026

Stanje

Novi

Lokacija

Kronberg im Taunus

Slike prikazuju

Prikaži kartu

Podaci o mašini

- Naziv mašine:

- Depaneliranje / Obrada PCB-a

- Proizvođač:

- Systemtechnik Hölzer GmbH

- Godina proizvodnje:

- 2026

- Stanje:

- novo

- Funkcionalnost:

- potpuno funkcionalan

Cijena i lokacija

- Lokacija:

- Westerbachstraße 4, 61476 Kronberg im Taunus, Deutschland

Pozovite

Detalji ponude

- ID oglasa:

- A18369436

- Referentni broj:

- LOW4233 RD XL Leiterplatten Nutzentrenner

- Ažuriranje:

- posljednji put 26.01.2026

Opis

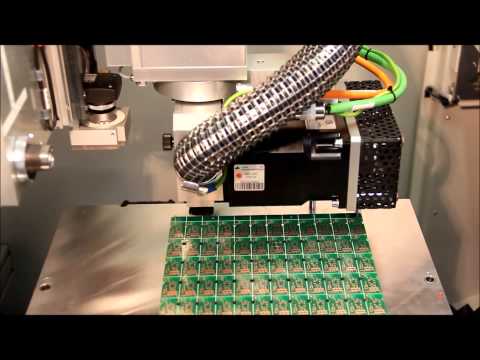

Semi-automatic depaneling / basic machine with parallel shuttle

The dynamic depaneling machine LOW 4322 XL is especially suited for medium to high product volumes and meets growing demands in the production process. Printed circuit board blanks of various materials are separated using low-dust and low-stress sawing and milling techniques with maximum product flexibility, precision and throughput. Highly dynamic linear motor axes, tools and grippers meet the highest quality requirements and guarantee the depaneling machine a long service life and high reliability.

Semiautomatic depaneling - solutions on demand

The LOW 4322 XL depanelling machine enables fast product changeover while maintaining short depanelling and handling times. The blank printed circuit board is inserted with a parallel shuttle, picked up and fixed with pin clamping technology and, if necessary, in combination with vacuum suction cups.

Made in Germany

The machine is equipped with:

- a shank and slice tool separation module on Z-axis (automatically rotatable 0-90)

- X-Y cross table module in linear motor technology with high-resolution measuring system

- 2-compartment loading module built as parallel shuttle, separated left and right with sliding doors

- Steel welding frame with two maintenance doors - left and right. ESD

- standard vision system base module for teach-in programming

- Working area is 520 x 480mm

- Automatic cutter length processing

- Remote maintenance/support via remote connection

- Touch IPC with Windows 10 Pro operating system

- Laser axis measurement incl. protocol

- Air ionization

- Cutter breakage control for end mills only

- Preparation for vacuum clamping technology

- ESD powder coating, RAL 9002, disc and sliding doors

Njdpjvuw R Refx Afaswc

Optionally a vacuum cleaner unit can be offered later.

The dynamic depaneling machine LOW 4322 XL is especially suited for medium to high product volumes and meets growing demands in the production process. Printed circuit board blanks of various materials are separated using low-dust and low-stress sawing and milling techniques with maximum product flexibility, precision and throughput. Highly dynamic linear motor axes, tools and grippers meet the highest quality requirements and guarantee the depaneling machine a long service life and high reliability.

Semiautomatic depaneling - solutions on demand

The LOW 4322 XL depanelling machine enables fast product changeover while maintaining short depanelling and handling times. The blank printed circuit board is inserted with a parallel shuttle, picked up and fixed with pin clamping technology and, if necessary, in combination with vacuum suction cups.

Made in Germany

The machine is equipped with:

- a shank and slice tool separation module on Z-axis (automatically rotatable 0-90)

- X-Y cross table module in linear motor technology with high-resolution measuring system

- 2-compartment loading module built as parallel shuttle, separated left and right with sliding doors

- Steel welding frame with two maintenance doors - left and right. ESD

- standard vision system base module for teach-in programming

- Working area is 520 x 480mm

- Automatic cutter length processing

- Remote maintenance/support via remote connection

- Touch IPC with Windows 10 Pro operating system

- Laser axis measurement incl. protocol

- Air ionization

- Cutter breakage control for end mills only

- Preparation for vacuum clamping technology

- ESD powder coating, RAL 9002, disc and sliding doors

Njdpjvuw R Refx Afaswc

Optionally a vacuum cleaner unit can be offered later.

Dobavljač

Napomena: Registrujte se besplatno ili prijavite, za pristup svim informacijama.

Registriran od: 2018

Pošaljite upit

Telefon & Faks

+49 6173 ... oglasi

Ovi oglasi bi vas također mogli zanimati.

Mali oglas

Matelica (MC)

Matelica (MC)

384 km

MAŠINE ZA LASERSKO REZANJE - LASERSKO REZANJE VLAKANA

PRIMA POWERPLATINO FIBER 1530

PRIMA POWERPLATINO FIBER 1530

Mali oglas

Butzbach

Butzbach

993 km

Obradni centar

Starrag-HeckertHEC500D

Starrag-HeckertHEC500D

Mali oglas

Njemačka

Njemačka

1.122 km

Venjakob Perfect sistem farbanja, OIR, AirJet, UV

VenjakobVEN SPRAY and Drying, UV Line

VenjakobVEN SPRAY and Drying, UV Line

Mali oglas

Burghaun

Burghaun

962 km

Morski kontejneri

db-container20fuß

db-container20fuß

Mali oglas

Borken

Borken

1.194 km

Staklo pvb s 2 grijača

Tool-TempHVD-G02

Tool-TempHVD-G02

Mali oglas

Bad Waltersdorf

Bad Waltersdorf

387 km

Stol za podizanje i rezanje stakla

Hegla

Hegla

Mali oglas

Władysławowo

Władysławowo

1.147 km

Digitalni štampački stroj

DIP TECHGlassJet NOVO

DIP TECHGlassJet NOVO

Mali oglas

Herzogenrath

Herzogenrath

1.165 km

Mašina za bušenje stakla

SchramlTop Clear 13 Special- 4

SchramlTop Clear 13 Special- 4

Mali oglas

Butzbach

Butzbach

993 km

Obradni centar

Starrag-HeckertHEC400D

Starrag-HeckertHEC400D

Mali oglas

Racibórz

Racibórz

690 km

GIĘTARKA DO RAMEK DYSTANSOWYCH

LISECBSV-45

LISECBSV-45

Vaš oglas je uspješno izbrisan

Došlo je do greške